Bulk tungsten carbide manufacturing and custom design services play a crucial role in various industrial sectors, including automotive, aerospace, mining, and tooling industries. Tungsten carbide is a composite material known for its exceptional hardness, wear resistance, and ability to withstand extreme conditions. These properties make it an ideal choice for applications requiring durable components that maintain performance over extended periods. Companies specializing in bulk production of tungsten carbide focus on delivering high-quality materials efficiently while meeting the specific demands of their clients.

The manufacturing process typically begins with the selection of raw materials such as tungsten powder and carbon black. These ingredients are carefully measured and mixed to achieve the desired chemical composition. The mixture then undergoes a sintering process where heat and pressure consolidate the powders into a dense solid form without melting them completely. This step is critical because it determines the final mechanical properties of the product, including toughness and hardness. Advanced techniques like hot isostatic pressing may also be employed to enhance density uniformity and reduce internal defects.

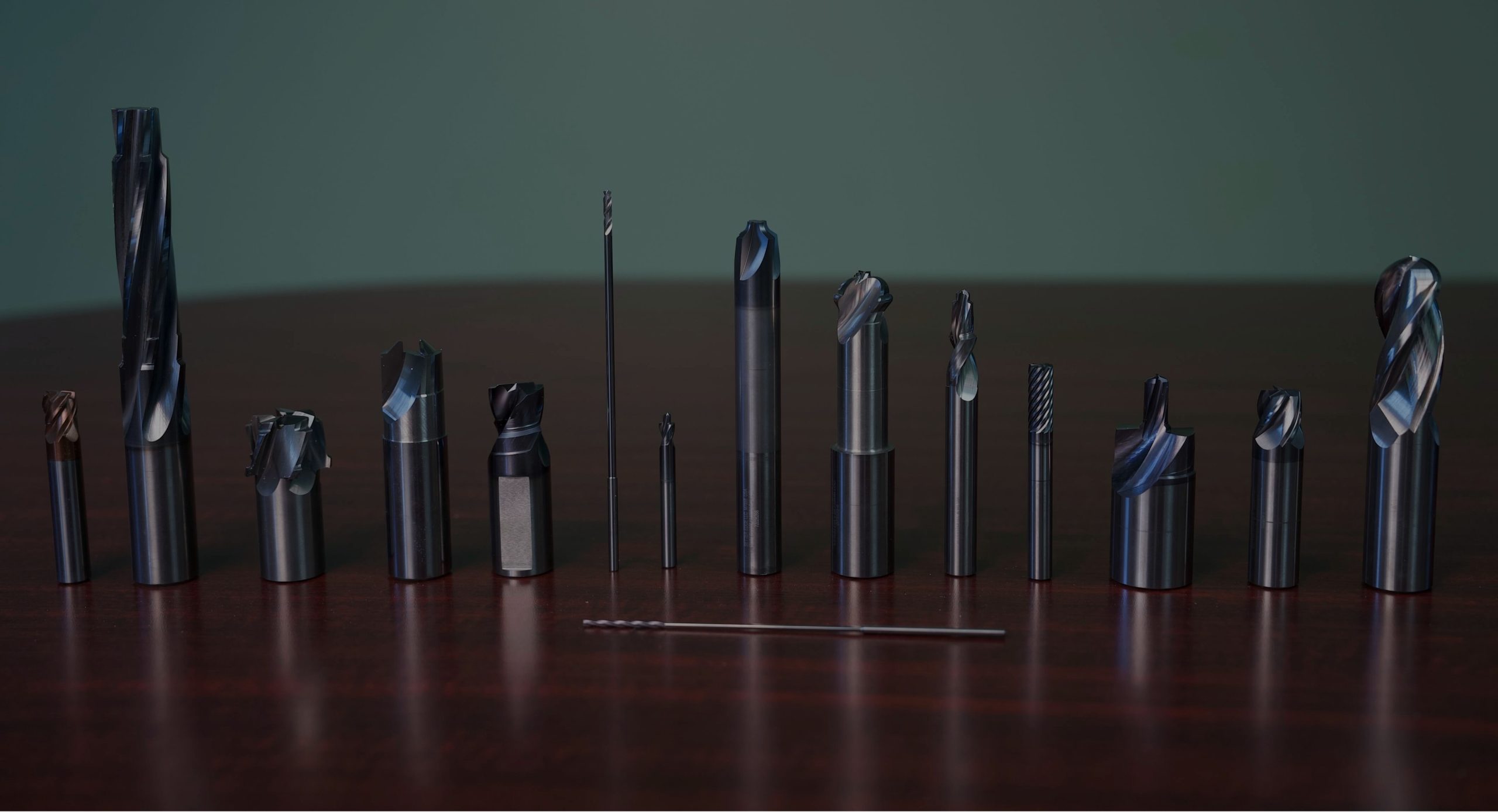

Custom design services complement bulk manufacturing by offering tailored solutions that address unique project requirements. Many industries require specialized shapes or sizes beyond standard offerings to optimize performance or fit within complex assemblies. Customization can involve intricate machining processes such as grinding, cutting, or polishing to achieve precise dimensions and surface finishes. Engineers work closely with clients during this phase to ensure that designs meet functional specifications while maintaining manufacturability standards.

Another important aspect of custom tungsten carbide Extramet Products involves coatings or treatments that improve corrosion resistance or reduce friction depending on application needs. Surface engineering methods like chemical vapor deposition (CVD) or physical vapor deposition (PVD) allow manufacturers to apply thin films onto parts without compromising their structural integrity. Such enhancements extend component lifespan significantly under harsh operating environments.

Quality control remains paramount throughout both bulk production and custom fabrication stages. Rigorous testing protocols evaluate hardness levels using standardized scales like Rockwell or Vickers tests alongside microscopic inspections for microstructural consistency. Dimensional accuracy checks verify adherence to client specifications before shipment occurs.

In summary, companies engaged in bulk tungsten carbide manufacturing combined with custom design capabilities provide essential materials engineered for durability across diverse industrial uses. Their expertise ensures reliable supply chains while accommodating specialized requirements through advanced processing technologies and collaborative development efforts with customers worldwide seeking superior performance solutions from this versatile material class.

Extramet Products

2890 Ligonier St, Latrobe, Pennsylvania 15650

724-532-3041